Monthly Deals Custom Anodized Aluminum 6061/7075 CNC Machining Parts for Electric Scooter

Ningbo Yongnan Machinery Factory was set up in 2009 with an area of 9,000 square meters . The company specializes in mou;

Basic Info

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 3 |

| Certification | RoHS, ISO 9001:2000 |

| Address | Ning Bo |

| Company | Factory |

| Experience | More Than 10 Years |

| Brand Name | OEM |

| Tolerance | 0.005mm |

| Service | One Stop-Shop Service |

| Transport Package | Seaworthy Packaging |

| Specification | 0.2-1 |

| Trademark | yongnan |

| Origin | China |

| HS Code | 8408201010 |

| Production Capacity | 100000 |

Product Description

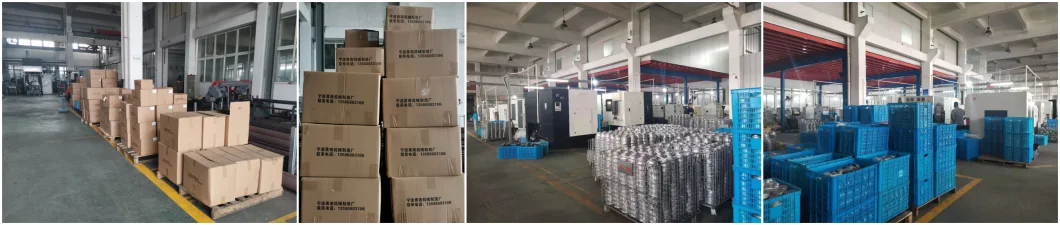

Ningbo Yongnan Machinery Factory was set up in 2009 with an area of 9,000 square meters . The company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts and precise gear hobbing. The company not only establishes a stable strategic relationship with domestic first-class motor companies, but also exports to Europe, United States, Japan and other countries. Ningbo Yongnan Machinery Factory provides one-stop shop that involves mould development, designing tool and fixture, aluminum die-casting, CNC and painting . The company has more than 100 equipment which cover 20 sets of precise four & five-axis machines; 2 sets of gear machines; 4 sets of robot arms; 60 sets of precise turning-milling and multi-station machines; 20 sets of multi-axis drilling machines; 3 sets of die-casting machines; advanced detector equipment and automatic painting line . The company has 87 employees which include 12 management staff, 5 senior engineers, 10 technical staff, and 10 QC staff. It has passed the quality management system standard: GB/T19001-2016 idt ISO9001:2015. In 2019, the company participated in the "Hundreds of Enterprise Promotion" project, actively promoted digital transformation of the industry and introduced the advanced Neural-MOS intelligent production operating system V6.0. Pursuing breakthroughs with reforms, promoting improvement with innovations; seeking development with quality, building brands with integrity; winning customers with service and promoting development with win-win are the values that our company has always adhered to. Our company is always committed to providing customers with higher quality products.| One-Stop Shop Service: | Mould design and manufactureDesigning tool and ficxureAluminium alloy die casting ADC12 A380Turning-milling, drilling and CNC machiningSurface treatmentFull inspectionPacking |

| Equipment | Die casting machine:200T/280T/400T/500T.CNC centers, CNC turning, CNC lathes,milling, multi-axis drilling, Automatic painting line |

| Surface Treatment | Polishing,Cleaning,Painting( Black or Silver ) |

| Application | E-bike Motor E-scooter Bike |

| Staff | 12 management staff 5 senior engineers10 technical staff10 QC staff 50 workers |

Our Advantages:

1.One stop-shop service to our customers.2. Customized with client's requirement3.Closing to Beilun port & Saving transportation distance3.Equipped with all kinds of Machines4.More than ten years experience

FAQQ1:Are you manufacturer?

A: Yes, we are. Our company was set up in 2009 with an area of 9,000 square metersQ2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order.

Q3:How to control the quality?

A:We have QC department and do full inspection for production.Q4:What kind of businesses can your provide?

A: Our company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts,precise gear hobbing and automatic painting line. Q5:Why do we need3D file and 2D drawing?

A:The 3D file is very useful,but there are some other requirement not indicated like the tolerance and the surface treatment .This is why the 2D file is needed

FAQQ1:Are you manufacturer?

A: Yes, we are. Our company was set up in 2009 with an area of 9,000 square metersQ2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order.

Q3:How to control the quality?

A:We have QC department and do full inspection for production.Q4:What kind of businesses can your provide?

A: Our company specializes in mould development, designing tool and fixture, machining of e-bike motor parts, e-scooter parts,precise gear hobbing and automatic painting line. Q5:Why do we need3D file and 2D drawing?

A:The 3D file is very useful,but there are some other requirement not indicated like the tolerance and the surface treatment .This is why the 2D file is needed

You may also like

Send inquiry

Send now